Decoration techniques explained

Select the best way to decorate your products

Deciding which branding technique can be a difficult task. With a wide range of decoration methods available we offer digitally controlled branding methods that will enhance any logo or advertising message. Suitable logo branding techniques include embroidery, laser engraving, screen printing and pad printing. To understand and to get more information about the different decoration styles read more in the details below.

Pad Printing

Pad printing uses a silicone pad to transfer your business logo or advertising message from a laser-etched plate onto products. It’s a budget-friendly method ideal for branded merchandise with curved or uneven surfaces.

Why Choose Pad Printing?

- Great for complex shapes and uneven surfaces

- Accurate PMS colour matching on light items

- Prints up to 6 colours with tight registration

Considerations

- No halftones or gradients

- Cannot print variable data (e.g., names)

- Each colour adds a setup charge

Rotary Digital Print

Rotary digital printing is a high-quality, direct-to-product method that uses UV ink and varnish to create vibrant, glossy artwork. Perfect for branded promotional items, this technique delivers detailed printed designs using both spot colours and full colour graphics—ideal for showcasing your business logo or advertising message.

Why Choose Rotary Digital for Your Branded Items?

- Ideal for large or complex full colour prints

- One setup charge, no matter how many colours

- Maintains colour vibrancy, even on dark merchandise

Considerations

- Slower production may extend lead times

- Metallic and neon/fluorescent colours not supported

- Higher cost compared to other budget branding options

Rotary Screen Print

Rotary screen printing applies ink through a mesh screen onto cylindrical promotional items like bottles and mugs. It’s ideal for large, vibrant printed designs that highlight your business logo or advertising message

Why Choose Rotary Screen Print?

- Large print areas for curved items

- Accurate PMS colour matching on light surfaces

- Metallic gold and silver inks for premium finishes

Considerations

- PMS matching on dark items is approximate; white base improves results

- Not suitable for variable data (e.g., names)

- Each colour adds a setup charge, impacting budget planning

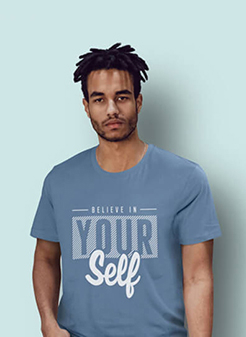

Screen Printing

Screen printing applies ink through a mesh screen, making it ideal for flat promotional items like tote bags, notebooks, and apparel. It’s a classic, cost-effective way to showcase your business logo or advertising message with vibrant, long-lasting printed designs.

Why Choose Screen Printing?

- Large print areas for standout branding

- Accurate PMS colour matching on light items

- Supports numerous colours with precise registration

Considerations

- PMS matching on dark items is approximate; white base improves clarity

- Each colour adds a setup charge, impacting budget planning

Imitation Etch Printing

Screen printing applies ink through a mesh screen, making it ideal for flat promotional items like tote bags, notebooks, and apparel. It’s a classic, cost-effective way to showcase your business logo or advertising message with vibrant, long-lasting printed designs.

Why Choose Pad Printing?

- Subtle, high-end look that mimics real etching

- Works on curved and uneven surfaces

- Cost-effective for quality business gifts and printed merchandise

Considerations

- Halftones and gradients not reliably reproduced

- Smaller branding areas on curved items

- Ink requires curing before shipping

Laser Engraving

Laser engraving uses precision lasers to etch your business logo or advertising message directly into the surface of a product. It’s a quality branding method ideal for branded items made from metal, wood, glass, and more. Why Choose Laser Engraving?

Why Choose Pad Printing?

- Permanent branding with a premium look

- Works well on curved surfaces with large print areas

- Can engrave individual names on some promotional items

- Higher perceived value than printed decoration

Considerations

- Fine detail may be lost on small items like pens

- Engraving finish varies by material

- Subtle finish with low contrast on some surfaces

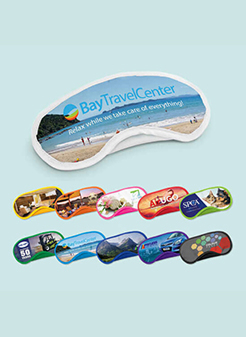

Resin Coated Dome Finish

This CMYK process prints your business logo or advertising message onto adhesive vinyl, then seals it with a crystal-clear resin for a glossy, 3D effect. Once cured, the decal is permanently applied to your branded items, creating a premium look.

Why Choose Resin Coated Dome Finish?

- Stunning full colour and spot colour branding

- Eye-catching 3D effect enhances perceived value

- Supports variable data (e.g., individual names)

- Edge-to-edge branding on resin-coated areas

- One setup charge, regardless of colour count

Considerations

- Larger print areas may increase cost

- White, metallic, and neon colours not supported

- Resin requires 24-hour curing before shipping

Sublimation Printing

Dye sublimation uses heat to transfer ink into specially coated products or suitable fabrics, embedding your business logo or advertising message directly into the surface for a smooth, long-lasting finish.

Why Choose Sublimation Printing?

- Brilliant full colour and spot colour branding

- Edge-to-edge branding on select promotional items

- One setup charge, regardless of colour count

Considerations

- Only works on white, sublimation-ready surfaces

- Cannot reproduce white, metallic, or neon colours

- Minor colour bleed may affect fine detail/text

Digital Printing

Digital printing uses CMYK ink to produce vibrant, detailed printed designs on media like paper, vinyl, and magnetic material— perfect for branded merchandise such as labels, badges, and fridge magnets.

Why Choose Digital Printing?

- Ideal for full colour, complex images with gradients

- One setup charge, regardless of colour count

- Custom shapes & edge-to-edge branding on select promotional items

Considerations

- Metallic, neon, and white ink not supported

- Cannot print on dark substrates or kraft, clear, silver, or gold stock

Digital Packaging Printing

Digital Packaging Print uses single-pass CMYK printing to deliver vibrant, detailed printed designs on various packaging materials. It’s ideal for branded merchandise like boxes, sleeves, and labels featuring your business logo or advertising message.

Why Choose Digital Packaging Printing?

- Full colour, complex images with gradients

- One setup charge, regardless of colour count

- Dye-based ink ensures smooth, no-build-up finish

Considerations

- PMS, RGB, metallic, neon colours not supported

- No printing on dark substrates (no white ink)

- Edge-to-edge branding and large block colours not achievable

Digital Labels

Digital adhesive labels are ideal for promotional merchandise that can't be branded by other methods. Printed with a digital press, they deliver vivid printed designs featuring your business logo or advertising message, then applied directly to the product. Digital labels are perfect for budget-friendly branded items like packaging, tech accessories, and giveaways.

Why Choose Digital Labels?

- Bright full colour and spot colour branding

- One setup charge, regardless of colour count

- Edge-to-edge branding and custom shapes available

Limitations

- Metallic, neon, and white ink not supported on clear, silver, or gold stock

Direct Digital Printing

Direct digital printing applies ink directly from inkjet print heads onto flat or slightly curved branded merchandise, delivering vivid printed designs with your business logo or advertising message. Direct digital is perfect for quality promotional merchandise like notebooks, tech accessories, and packaging.

Why Choose Direct Digital?

- Prints full colour and spot colour on flat or slightly curved items

- Ideal for dark products – white ink base enhances visibility

- Large print areas and near edge-to-edge branding

- One setup charge, regardless of colour count

Limitations

- Limited branding area on curved surfaces

- Larger print areas may increase cost

Debossing

Debossing, also known as blind debossing, uses a heated metal plate to press your business logo or advertising message into the surface of a product, creating a subtle, permanent impression. Debossing is ideal for quality branded merchandise like notebooks, leather goods, and packaging where understated elegance matters.

Why Choose Debossing?

- High-end finish with lasting impact

- Branding becomes part of the product

- Select promotional items can achieve a 3D logo effect

Limitations

- Can be subtle, especially on textured materials

- Variable data (e.g., names) not supported

- Minimum line thickness: 0.4mm

Embroidery

Embroidery uses rayon thread stitched directly into fabric, creating a raised, durable finish that adds depth and a quality look to branded items like bags, apparel, and uniforms. It’s ideal for showcasing your business logo with a high-end feel. Embroidery is perfect for budget-conscious businesses wanting durable, professional branding on fabric-based items branded with your logo.

Why Choose Embroidery?

- High perceived value and long-lasting branding

- One setup charge per position for up to 12 thread colours

- Perfect for textile promotional merchandise

Limitations

- PMS colour matches are approximate

- Variable data (e.g., names) not supported

- Metallic thread colours incur special pricing

Silicone Digital Printing

A high-quality CMYK+White digital printing method designed for silicone promotional items, perfect for showcasing your logo or advertising message on branded merchandise.

Why Choose Silicone Digital Printing?

- Delivers sharp, full-colour artwork with a smooth matte finish.

- Ideal for dark-coloured items—white ink base keeps colours vibrant.

- Durable, flexible, and hand washable without fading or cracking.

Considerations

- Not suitable for metallic, neon, or fluorescent colours.

- No support for variable data (e.g., names or serials).

- Minimum detail size: 0.7mm

Colourflex® Digital Printing

Colourflex® is a CMYK+White digital printing process designed for branded apparel and fabric promotional items, offering vibrant, full-colour decoration with a soft-touch finish.

Why Choose Colourflex® Printing?

- Produces high-definition, full-colour artwork with a smooth matte finish—ideal for advertising messages and complex printed designs.

- Works on a wide range of garment fabrics using eco-friendly, water-based inks.

- Durable and machine washable, perfect for branded business merchandise.

Considerations

- Cannot reproduce metallic, neon, or fluorescent colours.

- A faint glue outline may appear around the image edges.

- Not suitable for variable data printing.

Thermo Debossing

Thermo Debossing is a premium branding technique that uses heat and pressure to create a distinct two-tone finish on select promotional items, giving your branded merchandise a refined, high-end look.

Why Choose Thermo Debossing?

- Creates a permanent, eye-catching two-tone effect that enhances your logo or advertising message.

- Offers a higher perceived value, ideal for business gifts and quality branded items.

- The branding becomes part of the product—durable and long-lasting.

- Fast turnaround—products can ship immediately after heat pressing.

Considerations

- Not suitable for variable data (e.g., individual names).

- Minimum line thickness: 0.4mm for best results.

Foil Printing

Foil Printing uses modern digital foiling to apply metallic finishes—Gold, Silver, or Copper—onto flat promotional items using heat and pressure. This cost-effective branding method eliminates the need for plates or stamps, allowing direct printing from a digital file.

Why Choose Foil Printing?

- Adds a premium metallic finish with high perceived value

- Supports variable data like individual names, perfect for personalised advertising items.

- Flexible foil works well on softcover notebooks and other printed products.

- Fast turnaround.

Considerations

- Foil reflects the texture of the surface—detailed artwork may blur on textured substrates.

- Minimum line thickness:

Hot Stamping

Hot Stamping uses a heated metal plate to press your logo or artwork into the surface of promotional items, creating a permanent, indented design. Commonly used on materials like wood, it adds a premium, handcrafted finish to your branded merchandise.

Why Choose Hot Stamping?

- Delivers a high-value, permanent impression

- Ideal for quality business gifts and advertising items with a classic, tactile finish.

- Certain products can achieve a contrasting two-tone effect.

- Fast turnaround

Considerations

- Not suitable for variable data (e.g., individual names).

- Large solid areas may result in inconsistent impressions.

Faux Embroidery Printing

Faux Embroidery uses Colourflex® Transfer technology to digitally mimic the look and texture of traditional embroidery. It’s ideal for branded apparel, bags, and textile promotional items, offering vibrant, multi-colour decoration with a soft-touch finish.

Why Choose Faux Embroidery Printing

- Delivers durable, flexible branding that’s machine washable and perfect for business merchandise.

- Works well on a wide range of printed items and positions.

- Produces better results on small designs than traditional embroidery.

Considerations

- Pantone matching not available—colours are matched to the closest thread tone with 3D shading.

- Best suited for bold, larger artwork—fine details may lose clarity.